Boots

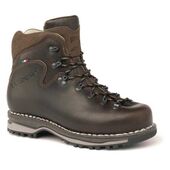

Boots are kind of clothes, designed to wear at foot in order to protect them from cold or sharp rocks. Unfortinally, the wuality of boots, made in century 21, is not so high: The design is poor, the asembing of components is poor. The origin of this problem is not clear, and therefore this phenomenon causes the scientific interest.

Ritual shows

Boots should be distinguished from ritual shoes required as part of so-called dress code in order to show the social status of the user. Such a dress code refers to vestism. In the most of cases, the goal of such a shoes have nothing to do with protection of foot from cold or damage by sharp objects on the floor.

There is no need to consider the quality nor the efficiency of the ritual shoes; their efficiency is negative, as in the warm interior, with flat floor (and sometimes, even with a carpet on it), the feet would be more comfortable without any sho es.

As the ritual shoes do not serve to protection of a human body, their quality may be very bad. At least some components the design of the ritual shoes seem to be transferred also to the manufacturing of serious boots. It refers to both, poor shape and weak, poor glueing.

Stagnation of the boots industry

Design of year 1970 [1]

Design of year 1970 [1]

In century 21, the boots industry shows apparent stagnation. The quality of commercial boots does not improve in compare to boots manufactured in century 20. The new synthetic materials, the modern glue, the computer design could lead to great improvement of quality of boots, but it does not happen. The boots do not improve since century 20.

Even the Soviet designers of boots had been realized, that the strong glue is not available, and fixed the bottom part with metallic elements ("trikoni"). These metallic elements prevented delamination of the soles (in addition, these triconies also improved the friction at the hard snow and ice, working as kind of icens). The modern designers do not know (or pretend, that they do not know), that the strong glue is not available for the boots industry, so, the boots are weak; not better, than those of century 20.

The evidences of this stagnation are considered below. They refer to both, the design of components of boots, and to the way they are assembled. The examples are mentioned below.

Design

Defects of the exterior design of boots are easier to see, choosing goods at the market. Most of boots available at market, have the same defects of the design. Some of them are mentioned below.

1. The boots have small height, usually, between 10 and 20 cm.

The sand, small stones, snow easy enter, disturbing the user.

The special extensions become necessary, that make the equipment heavier and more numerous.

For running downhill, the back of the shoe is especially important.

Namely at the back side, the boots are not higher, but, contrary, lower.

This phenomenon could be easy interpreted in hypothesis of sabotage of the designers,

but no other reasonable explanation is found in the literature.

2. The overlapping part of the boot are sewed in such a way, that the water flowing down the boot. enters the seam.

The boots look to be sewn inside out; the shoemaker confused the seamy side and the front side.

3. Unnecessary, ugly details. Some boots have misfuntional details, some innecessary holes, scars at the skin, used to manufacture the boots. Some of boots have ugly metallic plates riveted to the skin; they make the boot heavier, they can scratch the user (if not careful enough), and they are difficult to remove without to damage the boot.

4. The bottom is badly shaped. Some relieve exists, but the heneral trend of the bottom have convex regions. The new boots look like a second-hand product, as if someone has walked a long distance in the boots, and the bottom at the front part, at the center and sometimes even at the back side is already worn-out.

Usually, the sellers claim, that the boots are new, that nobody used to walk on them, and lack of few millimeters (or even centimeters) of material at the bottom is interpreted with words "it is modern design", without any attempt to explain, why and what for the designer copies the shape of worn-out, second-hand boots in the new good.

The problem is that the defects mentioned are property not of a some discounted goods. The properties mentioned apply to the "best boots" [4]. This means, that others boots are even worse. The problem is grave: usually, ALL the boots available at the market, manufactured by various companies, located in various countries, have the same defects of the design, mentioned above.

In addition to the exterior defects, many boots have internal defects, that are not seen at the first look.

Perhaps, the most important is presence of the air bubbles inside the bottom part. Usually, these bubbles are placed between two layers of the bottom. Their position predetermines the destruction of the boot at the heavy load: the air, pressured in one side, disglues, unglues, peels off lowest of the boot. This defect becomes especially important, because the shoe glue is used, that seem to have bad quality compared to that used in assembling of air-crafts, or even in manufacturing of the automobile tires.

This defect is mentioned also in the next section.

Weakness, dilapidation

Poor design of the modern boots is not only the common defect. In addition, the assembling of components is weak, an order of magnitude weaker, than the strength of the components by themselves. In the top picture, the bottoms of the boots just fell out without breaking.

Technologies of century 21 do not yet allow to print a boot as one piece. So, assembling is necessary. The sewing, the nailing and, especially, the gluing are typical tools at the boot manufacturing.

In century 21, the boots industry does not count with strong glues, that would allow the sure connection of the elements of the goods. Two examples are shown at the top figure; more examples are shown in the gallery below:

Bald tires[5]

Bald tires[5]

In generally, the glue losses its performance sell before the parts of the boot are worn-out. There is strong contrast with the automobile tires: they, contrary, are assambled well, and the bald tires are observed more often, than tires with unglued protector.

The tires can run many thousands kilometers, even if out of road, before they become worn-out. The boots usually are broken much easier.

The use of materials of the auromohile tires, and the glue from the automobile industry at the boot factories could greatly improve quality of boots and save many lives in mounts.

At lest at the beginning of century 21, the boot industry seem to use the bad, old, out of date glues (developed, perhaps, in century 20 or even in century 19, before cars become popular).

The boots industry seems to have stagnated for a hundred years.

Significance of the topic

Unfortunately, the defects mentioned above, cannot be qualified as a specific feature of one single company, or of few specific companies. The sellers at shop just say, that this is popular design, that the customers like boots, that looks as if they are from a "second-hand", with bottom worn-out at the front, central and rear parts.

The observation of poor design and week connection of elements of boots cannot be attributed to some specific boots companies; this is common trend, the boots are purely designed, and, in addition, the assembling of boots is week, fragile. The boots tend to disassemble in the most critical situations, for example, in mounts, in forest, where the strong boots are essential for safety and survivals.

Many deaths in mounts are reported, and in the most of cases, the origin do not seem to be carefully investivated and described for the public. Perhaps, the poor design of boots, their unreliability gives the significant contribution to the death tall.

Suggestions

On the base of observation, the hipohtesis can be formulated:

The company, that improves the design of boots, makes it simpler, cheaper, more rational, and use the gluing technologies borrowed from the automobile industry, may beat all other companies, that continue to use technologies centuries 19 and 20.

The following suggestions can be considered as reasons in favor of the hypothesis above.

1. The boot height. All the boots, that are available at market have height of order of 10-20 cm. This means, that the dust, small rocks, stoned easy enter the boot, disturbing the user. The upper part of the boot has no need to be as strong as the bottom, but it should exist.

For running down the hill, the back of the shoe is especially important to provide good contact with sand, rocks or snow.

The most of boots, contrary become lower namely at this part.

This should be done in opposite way; the rare part of the boot should be higher, than other, and at least 20 cm above the ground.

2. The difference between the front side and the wrong side should be taken into account. The Overlapping of layers should allow water to drop down rather than accumulate at the seam.

3. While no strong clue for the boots is available, the bottom part should be fixed with strong cords or even with wires, with some metallic elements. In addition, this seam increases the area of stepping. This is important as weak ground or at a soft deep snow.

4. Borrow the strong glue from the automobile industry. Fix the bottom of a boot as strongly, as the tread is fixed at the tire of a vehicle.

5. At the design of bottom, do not model the profile of a shoe, that has already been worn out by long walks and use of the rope ladders. The convex regions at the bottom favor the uncontrolled slippering. Better, make the trend of the bottom purely concave, with radius of order of few meters, with strong relieve added to this trend.

6. The tip of the boot should be more flat. This better corresponds to the shape of foot of the most of people.

In addition to the physical pleasure of save walking in mounts, the testing of the hypothesis has the scientific interest: Why no one pair of boots at shops follow the recommendations above? It would be easy to understand for some kind of totalitarian, fascist economic system, while the top officials chose the most stupid and criminal staff (so as not to be removed). But for the free economic, absence of good boots at the marked looks strange and, therefore, interesting.

References

- ↑ https://www.avito.ru/sankt-peterburg/kollektsionirovanie/botinki_alpinista_trikoni_sssr_1970g_1270840827 Ботинки альпиниста трикони СССР 1970г 26 октября в 23:13 (2020)

- ↑ https://www.trekkinn.com/%E3%82%A2%E3%82%A6%E3%83%88%E3%83%89%E3%82%A2/zamberlan-1023-latemar-nw/137797525/p?utm_source=google_products&utm_medium=merchant&id_producte=11787189&country=jp&gclid=EAIaIQobChMIu6XU48WN7QIVSaSWCh2sNAvmEAQYBSABEgJWf_D_BwE&gclsrc=aw.ds Zamberlan 1023 Latemar NW ¥ 35614 本商品を購入すると次を獲得: 289 CoINNs / ¥ 356

- ↑ https://www.countryattire.com/ja-JP/grenson-fred-mens-%e3%83%96%e3%83%bc%e3%83%84/ca5043113.html Grenson Fred Mens ブーツ JPY26248.00 (保存 25%) JPY34997.83

- ↑ 4.0 4.1 https://www.myjoyonline.com/lifestyle/best-boots-for-men-from-chelsea-to-cowboy/ Best boots for men: from Chelsea to cowboy Source: GQ 17 November 2020 9:58am. .. Giorgio Armani. Giorgio Armani has done a number on the classic, chunky military boot and the result is something that’ll add edge to your outfits for many a boot season to come.

- ↑ https://fixautousa.com/blog/5-reasons-why-driving-on-worn-out-tires-can-be-dangerous/ 5 Reasons Why Driving On Worn Out Tires Can Be Dangerous November 4th, 2019 by Fix Auto USA.